- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

|

| |

Our mango processing line is designed for commercial fresh-cut and frozen mango production. Combining automated mango peeling, manual pit removal, and mango cutting, the line ensures consistent output and high product quality while significantly reducing manual labor. Each station is carefully engineered to process mangoes gently, preventing bruising and fruit loss, which is critical for both domestic sales and export markets.

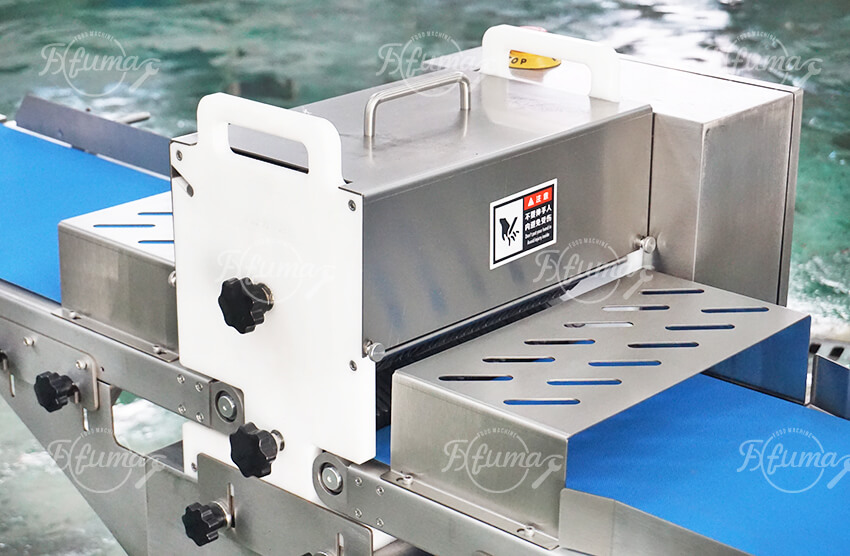

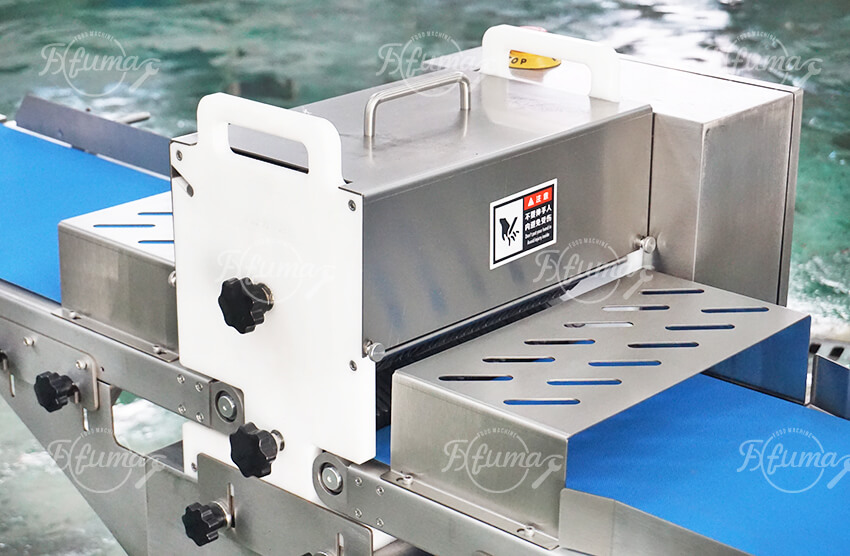

Unlike many conventional processing lines, this setup focuses not only on speed but also on hygiene and food safety. Stainless steel construction, smooth surfaces, and easy-to-clean components make daily sanitation simple and efficient, complying with FDA produce processing guidelines and Codex/FAO hygiene standards.

The workflow begins with mango feeding, where fruit is automatically aligned for peeling. The peeling station removes the skin without wasting flesh, maintaining the natural shape of the mango. Next, at the manual pit removal station, operators carefully remove the seeds, ensuring minimal fruit damage. Finally, the cutting stations slice mangoes into strips or cubes according to customer requirements. Each stage can be adjusted to accommodate different mango varieties and sizes, making the line highly flexible.

mango peeling

mango coring

mango shredding

Multi-stage Processing: Automated peeling, manual coring, and adjustable cutting.

High Productivity: Continuous workflow reduces labor while increasing output.

Hygienic Design: Stainless steel construction, easy to clean, compliant with FDA and international hygiene standards.

Customizable Output: Cut sizes, conveyor speed, and station layout can be tailored.

Integration Ready: Can connect with upstream washing systems or downstream freezing and packaging equipment.

Commercial mango fruit processing factories produce fresh-cut or IQF mangoes.

Export-oriented operations require strict compliance with international food hygiene standards.

Factories are looking to reduce labor costs while improving yield consistency.

Processing lines producing mango strips, cubes, or half-processed fruit for further packaging.

This mango processing line addresses common pain points in mango production. Manual peeling and coring often result in high labor costs, inconsistent fruit size, and waste. By combining automation with carefully designed manual steps, this line reduces waste, increases output consistency, and ensures fruit quality. Operators spend less time handling fruit directly, reducing bruising and contamination risks.

Flexible design allows for easy adjustment for different varieties, such as Tommy Atkins, Kent, or Keitt mangoes, and different product formats—strips for frozen snacks, cubes for fresh-cut packs, or semi-processed halves for further production. The line can be integrated into a larger production system, including washing, drying, freezing, and packaging, making it a complete solution for modern mango processing.

Our mango processing line is designed for commercial fresh-cut and frozen mango production. Combining automated mango peeling, manual pit removal, and mango cutting, the line ensures consistent output and high product quality while significantly reducing manual labor. Each station is carefully engineered to process mangoes gently, preventing bruising and fruit loss, which is critical for both domestic sales and export markets.

Unlike many conventional processing lines, this setup focuses not only on speed but also on hygiene and food safety. Stainless steel construction, smooth surfaces, and easy-to-clean components make daily sanitation simple and efficient, complying with FDA produce processing guidelines and Codex/FAO hygiene standards.

The workflow begins with mango feeding, where fruit is automatically aligned for peeling. The peeling station removes the skin without wasting flesh, maintaining the natural shape of the mango. Next, at the manual pit removal station, operators carefully remove the seeds, ensuring minimal fruit damage. Finally, the cutting stations slice mangoes into strips or cubes according to customer requirements. Each stage can be adjusted to accommodate different mango varieties and sizes, making the line highly flexible.

mango peeling

mango coring

mango shredding

Multi-stage Processing: Automated peeling, manual coring, and adjustable cutting.

High Productivity: Continuous workflow reduces labor while increasing output.

Hygienic Design: Stainless steel construction, easy to clean, compliant with FDA and international hygiene standards.

Customizable Output: Cut sizes, conveyor speed, and station layout can be tailored.

Integration Ready: Can connect with upstream washing systems or downstream freezing and packaging equipment.

Commercial mango fruit processing factories produce fresh-cut or IQF mangoes.

Export-oriented operations require strict compliance with international food hygiene standards.

Factories are looking to reduce labor costs while improving yield consistency.

Processing lines producing mango strips, cubes, or half-processed fruit for further packaging.

This mango processing line addresses common pain points in mango production. Manual peeling and coring often result in high labor costs, inconsistent fruit size, and waste. By combining automation with carefully designed manual steps, this line reduces waste, increases output consistency, and ensures fruit quality. Operators spend less time handling fruit directly, reducing bruising and contamination risks.

Flexible design allows for easy adjustment for different varieties, such as Tommy Atkins, Kent, or Keitt mangoes, and different product formats—strips for frozen snacks, cubes for fresh-cut packs, or semi-processed halves for further production. The line can be integrated into a larger production system, including washing, drying, freezing, and packaging, making it a complete solution for modern mango processing.