- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1985 Author: Site Editor Publish Time: 2024-03-27 Origin: Site

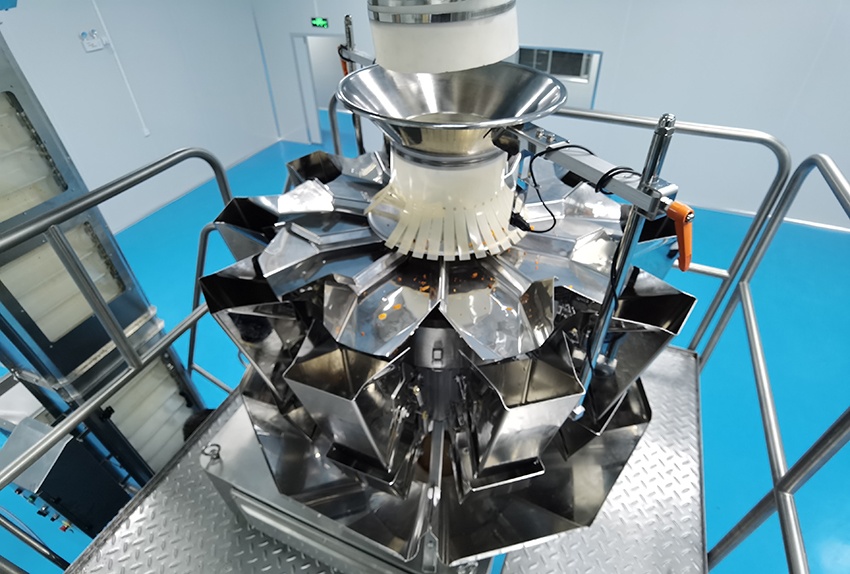

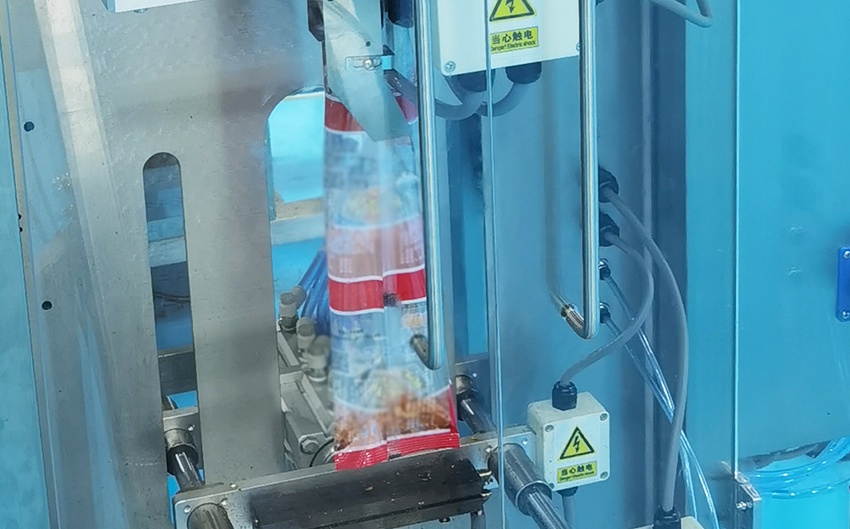

A snack food company in our country ordered a high-efficiency and large capacity fresh fried french fries and crisp production line, and the capacity is 50,000 tons per hour. This chips crips production line integrates various processes, including potatoes washing, cleaning, cutting and slicing, frying, seasoning and weight packaging. By replacing the cutter we can different shapes of fresh potato chips.

From cleaning raw potatoes to packaging finished products, this line is automated. This line make with high-quality stainless steel and food-grade conveyor belts. Each detail of the production line is controlled.

We've also arranged our service team to customer factory, assist our customers with installation and adjustments of equipment. Operational issues, or any other questions, we provide solutions quickly. Additionally, we offer regular production line maintenance for our customers.

Customer First, we are improving service quality and customer satisfaction. we strive to provide best services and higher-level products to provide long-term trust and support from our customers.

Advantages :

1)Complete potato chips production line with smart PLC controlling system.

2)Less worker operation.

3)With filtering system, which can easy to clean potatoes

4)Food standard raw material stainless steel and advanced configuration