- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 14680 Author: Site Editor Publish Time: 2024-05-10 Origin: Site

|

Description

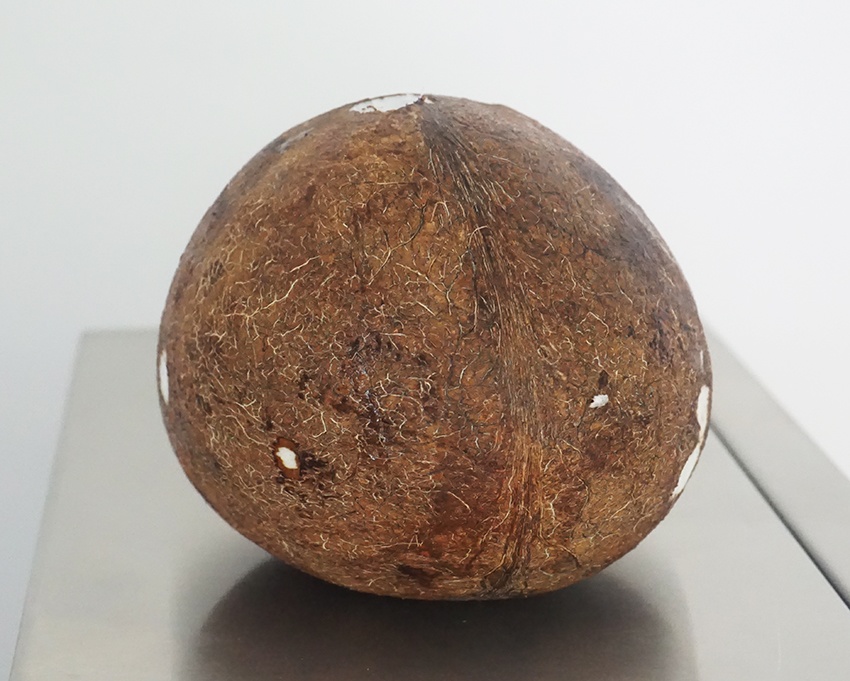

Coconut productions including variety of foods, beverages and other goods made from coconuts.

These products are usually derived from different parts of the coconut, such as coconut flesh, coconut water, husk and fiber, and are made through different processing methods. The following is an introduction to the equipment used from whole coconut to shredded coconut or dried coconut. The processing including removing the coconut hard shell, removing the coconut skin, obtaining coconut water, shredding the coconut, drying coconut flakes or grinding coconut.

|

Production Process

|  |

|  |

|  |

After removing the shell, our coconut peeling machine and coconut dehusking machine separate both outer husk and inner shell efficiently. According to different capacity, we can provide different coconut paring machine for your, and this machine also can be customized.

|  |  |

Once the coconut flesh is clean, then cut it into thin shreds. Usually use a shredding or slicing machine for this. The size and shape of the shreds can be adjusted according to the requirements of the final product.

|  |

|  |

|  |

Depending on the different coconut products, the coconut process will also be different. If your finished product is coconut flakes or coconut blocks, then the coconut needs to be cleaned after cutting. The coconut can be cleaned by bubble washing machine, and ultrasonic or ozone functions can also be added to improve the cleaning ability.

|  |

The shredded coconut is then dried to remove excess moisture, extending its shelf life and enhancing its texture.

|  |

Putting coconut onto the convey,then it transfer by the chain and reach the breaking part, High quality wearing blade auto half cut the coconut, the coconut water gathered into the hopper, the coconut shell comes out by the tilt of the landslide.

|  |

|

Our Service

With 19 years' professional experience

Selling well in 80+ countries

Serving 3000+ enterprises

1. We are always devoting our time and energy to the industry of food processing machinery, and to research, develop, deep work and innovate in the field of fruit and vegetable machinery, hoping that our service can meet customers' satisfaction, and our products can truly create value for our customers.

2. We adhere to the value of "customer-centricity". From the user's perspective, to design various practical solutions to make food processing easier and better, so that the processed food is safe, hygienic, tasty and nutritious.

3. Today, Fuma machinery, just like the founder's original intention, has flown to the world and continued to fulfill the dreams of many customers.

4. In the future, we are committed to becoming a "world-class service provider with our fruit and vegetable solutions".