- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

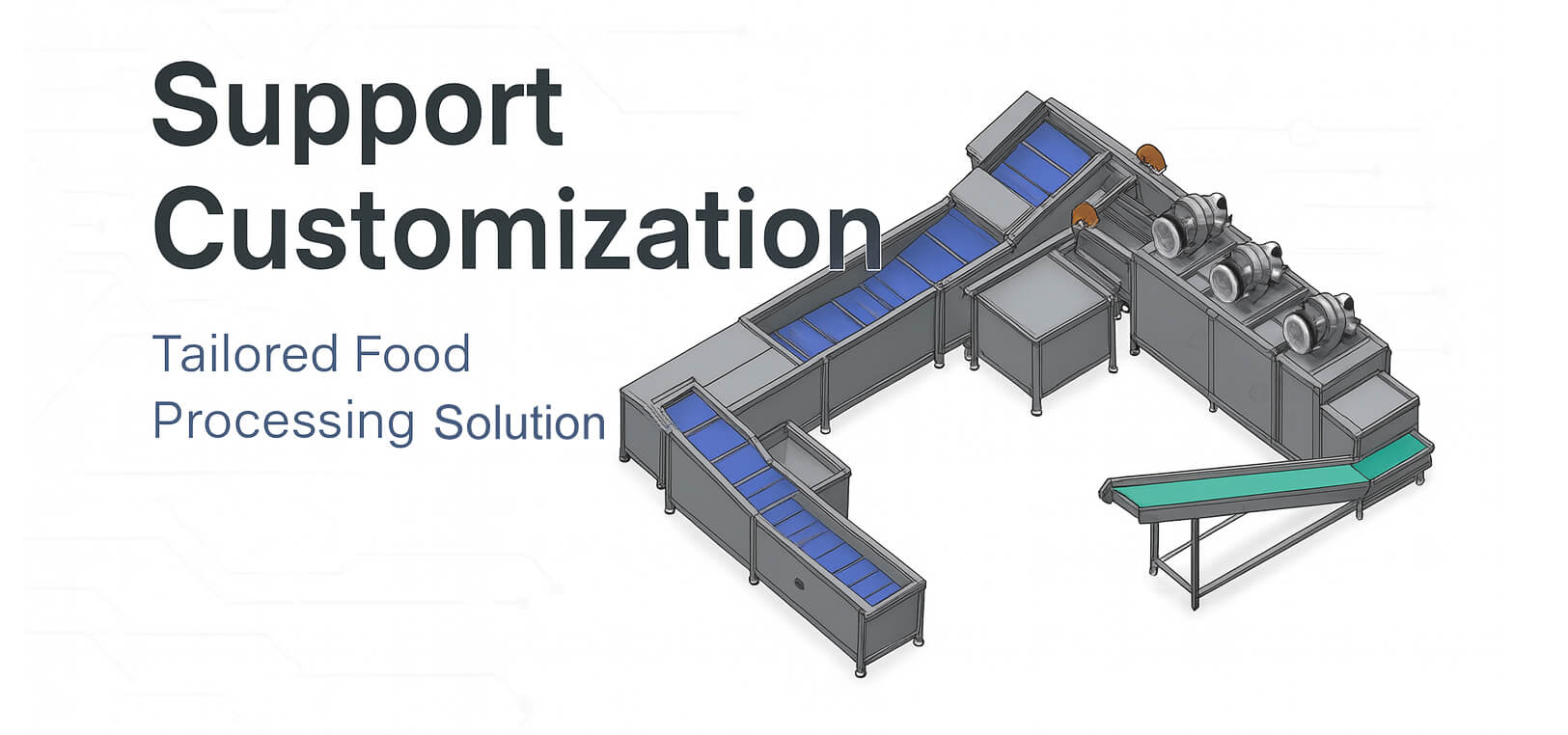

The salad processing line consists of a sorting table, multifunctional vegetable cutter, lifting conveyor, vortex-type washer, vibrating dewatering conveyor, and a continuous dewatering system. Designed for high-volume food producers, the line creates a fully connected workflow from raw material input to final moisture removal.

2.1 High Output Through Full Automation

A salad manufacturing facility in Southeast Asia integrated this line to replace its semi-manual operation. The equipment now handles cutting sizes from 1–60 mm, ensures precise material transfer through the elevator, and maintains stable cleaning and dewatering through synchronised washing and drying units.

The full system reaches up to 2,000 kg/hour, improving efficiency by more than 55% and enabling stable 8-hour continuous production.

2.2 Enhanced Cleaning Results and Controlled Moisture Levels

For customers processing lettuce, spinach, and other leafy vegetables, the vortex washer’s bubble circulation achieves a 92% pesticide-reduction rate. The two-stage moisture removal—vibration separation followed by continuous air dewatering—lowers surface moisture to below 15%, helping salads stay fresh up to 7 days, more than double the previous shelf life.

2.3 Flexible for Multiple Vegetable Categories

A European vegetable supplier uses the system to process both fragile leaves and dense root vegetables. Carrots and potatoes can be cut into uniform 10 mm cubes, while kale and baby spinach remain intact thanks to gentle handling.

3.1 Lower Labour Demand and Operating Costs

A central kitchen that formerly relied on eight workers shifted to only two operators after upgrading to this automated line. Daily output increased from 5 to 12 tons, reducing labour costs by over 65%. Its water-circulation system uses just 120 kg/hour, saving more than 800 tons of water annually compared with older washing methods.

3.2 Supporting Expansion Into New Markets

A Middle Eastern fruit and vegetable exporter achieved a monthly processing increase from 150 to 450 tons and gained access to European buyers due to stable cutting quality and consistent washing performance. Core components last up to 8 years, reducing depreciation and long-term maintenance costs.

Our engineering team has developed multiple proprietary technologies, including a three-stage cleaning system for vegetable washers. With 13 national utility model and design patents, the company also produces specialised machines such as its pumpkin peeler and broccoli floret processing system—equipment not offered by other domestic manufacturers.